350.000

SMT ve THT toplam

350.000 adet / saat malzeme

dizgi kapasitesi

No Clean And Lead Free

No clean ve lead

free üretim

IPC-A-610 & IPC J-STD-001

Sertifikalı Eğitim

Otomatik Kontrol (AOI)

SMT montajı tamamlanmış ürünler fırın sonrasında AOI cihazları ile otomatik olarak dizgi kalitesi kontrolüne tabi tutulmaktadır.

SPI

Solder Paste Inspection

Yıkama

Müşteri talebine bağlı olarak elektronik devreler kimyasal yıkama cihazlarımızda temizlenmektedir

0201 / 42mm

0402 ve üstü chips dizgi

ve 42mm ye kadar IC dizgi

Lehimlemede Azot Kullanımı

Lehimleme süreçleri elektronik devrenin oksitlenmesini ortadan kaldırarak daha iyi bir lehim bağlantısı sağlamak üzere Azot Gazı ortamında yapılmaktadır

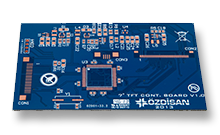

QFP,QFN,CSP

Ultra-fine pitch ,QFP,QFN, BGA,CSP

micro BGA dizgi

Yaşlandırma Testi (Temp/Humidity Chamber)

Montajı tamamlanmış ürünler müşteri talebine bağlı olarak ısıl yaşlandırma testlerine tabi tutulmaktadır

Fikstürsüz Test

Prototip ve düşük sayıdaki üretimler için “Flying Probe” olarak adlandırılan tam otomatik iğne dokunmalı test cihazı ile ürün testleri yapılabilmektedir.

Koruyucu Kaplama

Savunma sanayi veya endüstriyel ürünler için müşteri taleplerine bağlı olarak ürünlerin ortam şartlarından etkilenmemesi için otomatik makine ile koruyucu kaplama yapılmaktadır.

RoHS

RoHS compliant assembly

50 x 40

1200 x 350mm

PCB ölçüleri: Min : 50mm x 40mm

1200 x 350mm

PCB ölçüleri: Min : 50mm x 40mm

Max: 1200mm x 350mm

ICT Test (In-circuit Test) , FCT (Functional Test)

Üretilen ürünler %100 olarak teste tabi tutulmaktadır. Bu amaçla yüksek teknolojiye sahip test cihazları kullanılmaktadır. Müşteri talebine bağlı olarak ürünlere devre içi test sonrası fonksiyon testleri uygulanmaktadır

1200 x 350mm

1200 x 350mm